Advantages of multi-station thermoforming machines

Advantages of multi-station thermoforming machines

Multi-station thermoforming machines are highly efficient plastic processing equipment. Through continuous operation at multiple stations,

they heat, shape, and cut plastic sheets to produce various plastic products. They offer significant advantages in production efficiency, cost

control, product quality, and production flexibility. The table below summarizes their core advantages:

Areas of Advantage

Specific manifestations

Production efficiency

The process is centralized, continuous, and automated, with a speed of 10-50 molds/minute, supporting 24-hour operation.

Comprehensive cost

A single machine completes multiple processes, saving on equipment and space investment; automated production reduces labor costs; precise control reduces raw material waste.

Product quality

The molding process ensures uniform material distribution and consistent product wall thickness, thereby enhancing strength and durability; automation guarantees high precision and consistency of the product.

Operational flexibility

It is compatible with various sheet materials such as PET, PP, PS, PVC, as well as biodegradable PLA and corn starch. By changing the mold, it can quickly switch between different products to meet diverse production needs.

Purchasing Considerations

*After understanding the advantages of multi-station thermoforming machines, if you are considering purchasing such equipment, you should also pay

attention to the following points:

*Core Configuration is Key: The stability and precision of the equipment largely depend on its core components. When purchasing, focus on the brand

and quality of the servo system, major electrical components (such as PLC and touch screen), and bearings. For example, using servo systems and bearings

from well-known brands can effectively ensure the long-term stability and precision of the equipment.

*Understand the Manufacturer's Strength: In addition to the equipment itself, the manufacturer's technical expertise and support capabilities are also crucial.

An experienced manufacturer can not only provide stable equipment but also timely technical support and practical solutions.

*Clarify Your Needs: First, clarify the types of products you mainly produce (such as bowls, lids, boxes, plates, electronic trays, etc.), the types and thicknesses

of materials used, and your approximate production efficiency requirements. This will help you determine whether the forming area, applicable sheet materials,

and other parameters of a specific model match.

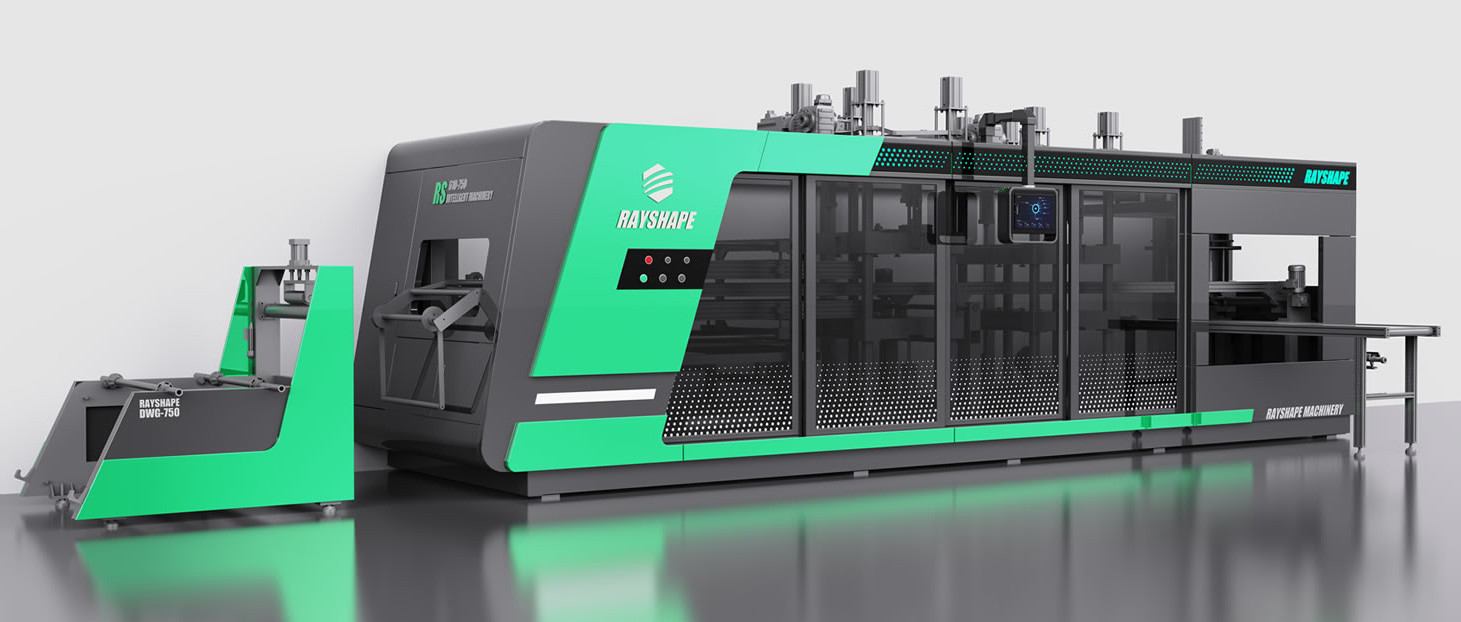

OUR MACHINE'S FEATURES AND ADVANTAGES

1. High degree of standardization, complete functions, safe, efficient, energy-saving and hygienic.

2. It integrates mechanical, pneumatic and electrical integration, and is controlled by microcomputer and programmable controller (PLC).

3. Easy-to-operate human-machine interface, and has the function of remote connection.

4. Electric lifting, double-station large-diameter unwinding, allowing a single person to load coils weighing up to 600KG.

5. Servo feeding, stepless adjustment of sheet length, high speed, accuracy and stability.

6. The upper and lower electric heating furnaces are used for four-stage heating and protection to reduce the impact of air convection on temperature,

so that the product molding is stable, from 0-400 degrees in just 3 minutes, improving production efficiency. The electric heating furnace can automatically

remove the device.

7. A new real-time distributed digital dynamic hot forming temperature control system is used to control the temperature of the tile at a single point, and it

has automatic compensation control, with an accuracy of ±1℃. Energy saving of about 15% and extended furnace plate service life.

8. The quick mold change system can conveniently, quickly, accurately and safely change molds, reduce machine downtime, reduce labor waste, and improve

production efficiency.

9. The mold opening and closing of the forming, cutting station are controlled by servo motor, with high precision, low wear, fast speed and low noise. Each

station is supported by four columns, combined with a five-point structural connecting rod, which has good stability.

10. The unique vertical stacking concept ensures continuous stacking of products.

11. Automatic counting of finished product output, with production data memory function, can store 90 sets of operating data.

12. Combined with the edge material winding device, the entire production process is clean, without burrs and waste.

13. The design of the electrical cabinet is simple and refreshing, simplifying the machine assembly and wiring installation process.