Five support point five axis motion system offers advantages in thermoforming machine

five-support-point (five-axis) motion system offers advantages in thermoforming machine

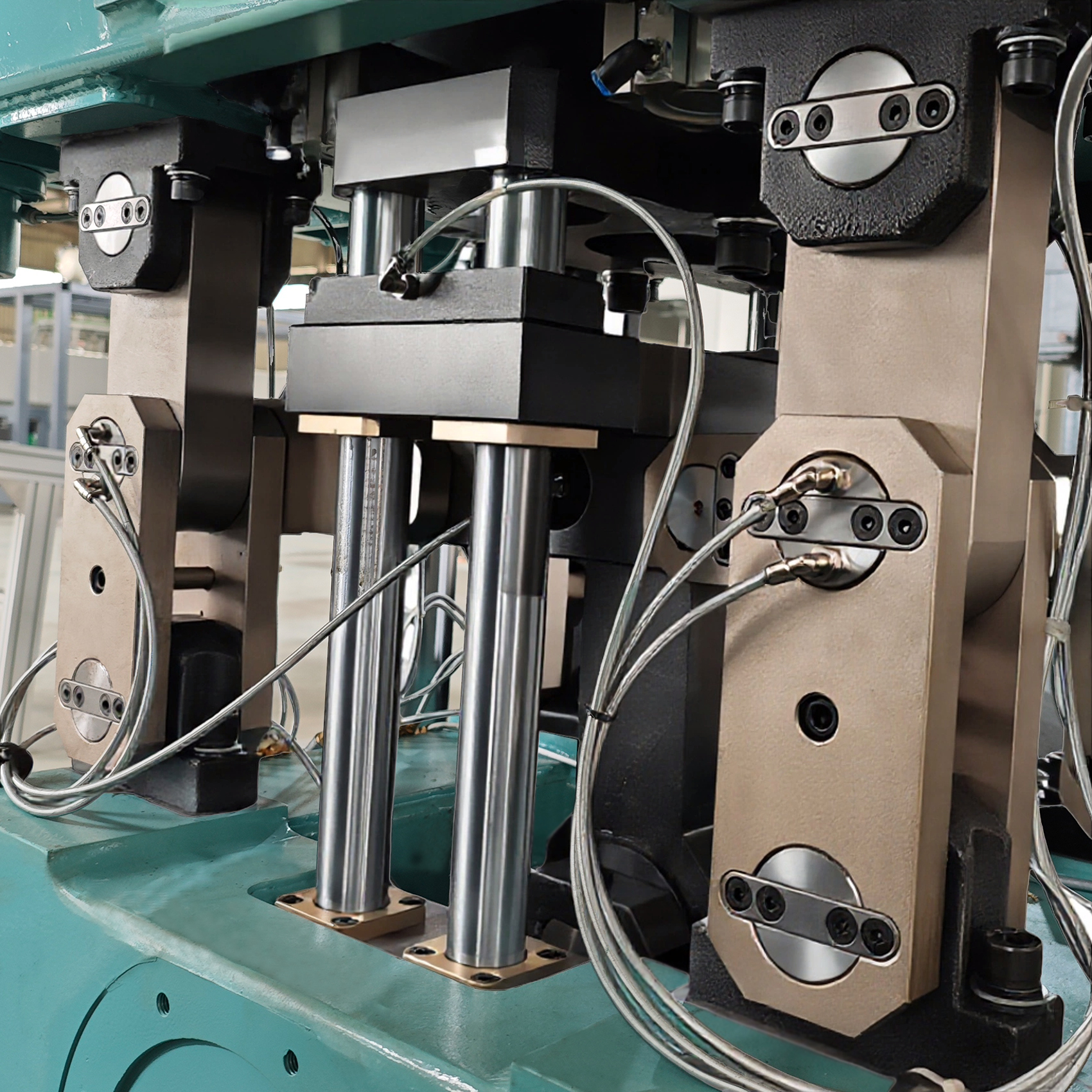

This concept typically refers to a motion system consisting of five support points (fulcrums) in the core forming or stamping mechanism of a machine.

Compared to traditional single-point, double-point, or four-point structures, the five-fulcrum design offers significant and crucial performance improvements.

Its core advantages can be summarized as follows:

Core Advantages at a Glance:

* **Superior Stability and Rigidity:** The five support points form a statically indeterminate structure, effectively counteracting off-center load moments and

preventing the moving plate from tilting or deforming under load.

* **Extremely High Motion Precision:** The stable structure ensures that the upper and lower die plates remain parallel during mold closing and punching

processes, resulting in extremely high repeatability.

* **Extended Equipment and Die Life:** Uniform force distribution significantly reduces wear and fatigue damage to guide rails, bearings, lead screws,

and the die itself.

* **Suitable for Large Forming Areas and Deep Drawing:** When forming large areas or performing deep drawing, the five-fulcrum structure is key to ensuring

product quality and production stability.

* **Improved Final Product Quality:** Stable pressure and precise mold closing ensure uniform product wall thickness, smooth, burr-free edges, and good consistency.

In-depth Analysis: The Principles Behind the Advantages

Unparalleled Stability and Rigidity

Principle: The five support points form a highly stable mechanical structure. When subjected to asymmetrical off-center loads (common in the production of large-area

or unevenly shaped products), the five support points generate effective torques to resist torsional moments, ensuring that the moving upper mold plate or movable

plate does not tilt like a seesaw.

Result: The entire mold closing and punching process is extremely smooth, avoiding impacts and vibrations caused by structural swaying.

Ensuring High Precision and Consistency of Products

Principle: Extremely high rigidity ensures that the upper and lower molds remain absolutely parallel during mold closing.

Result: For molding: The material has a uniform stretch ratio across all areas, resulting in consistent product wall thickness and preventing localized thinning or tearing.

For punching: Clean and crisp cuts, free of burrs and stringing, resulting in smooth and aesthetically pleasing product edges. The dimensions of each product are highly

consistent, significantly improving the yield rate.

Significantly Extends Equipment and Mold Life

Principle: Due to uniform force distribution, pressure is evenly distributed across five support points and the entire mold, avoiding the problem of excessive localized

stress in traditional structures.

Results: Wear and fatigue of key components such as guide rails, crankshafts (or lead screws), bearings, and the mold itself are significantly reduced. This translates to

less downtime for maintenance, longer mold life, and lower long-term operating costs.

Applicable Scenarios

A five-point station is not necessary in all situations, but its advantages are crucial in the following scenarios:

Large Sheet Forming: Such as producing large trays, refrigerator liners, bathtubs, automotive interior parts, etc.

Deep Drawing Products: Such as producing deep cups, bowls, lids, and other products requiring deep drawing.

High Precision Requirements: Such as producing medical trays, electronic packaging blister packs, and other products with extremely high dimensional tolerance requirements.

Using High-Strength Materials: When processing thicker or higher-strength sheets, greater clamping force and stability are required.

Summary

Choosing a five-point station thermoforming machine is essentially an investment in "stability," "precision," and "long-term reliability." Through its more advanced mechanical

structure, it fundamentally solves the various problems caused by off-center loading. Although the initial cost may be higher, for modern factories that pursue high-quality,

large-volume, and continuous production, the improved product yield, extended mold life, and increased production efficiency it brings make it a highly profitable choice.