Plastic Sheet Extruder-130-1000

Contact Details

INTRODUCTION

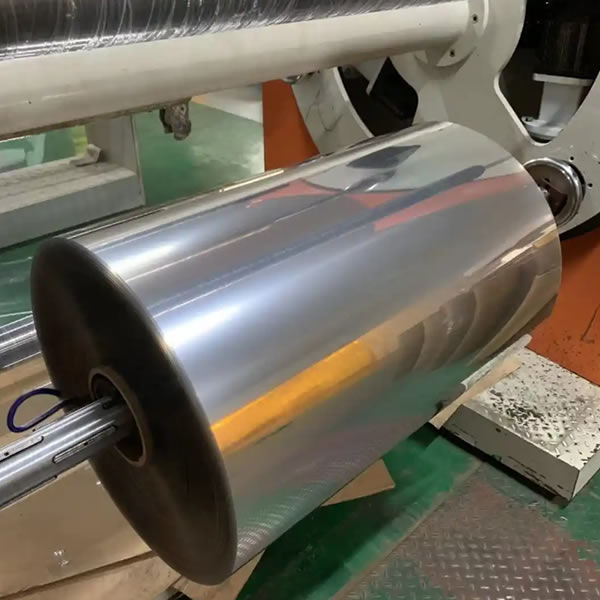

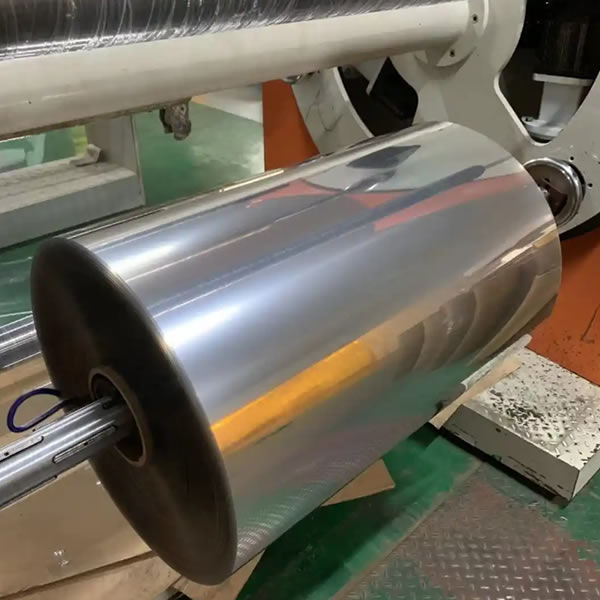

It is suitable for extruding plastic sheets such as polypropylene (PP), polystyrene (PS), and polyethylene (PE). The formed plastic sheets are used to make thermoformed packaging containers such as plastic trays, beverage cups, ice cream cups, yogurt cups, lids, plates, fruit boxes, and other printed products.

FEATURES AND ADVANTAGES

2. Integrated mechanical, pneumatic, and electrical systems, controlled by a microcomputer and programmable logic controller (PLC).

3. Easy-to-use human-machine interface with remote connection capability.

4. Major components, including the screw, barrel, screen changer, and die head, are constructed of high-quality alloy steel (38CrMOAIA) and nitrided for high hardness, corrosion resistance, and long service life.

5. Optimized screw design with a large aspect ratio ensures uniform plasticization, excellent mixing, and high production capacity.

6. The extruder frame is constructed of square steel, ensuring stable high-speed operation and continuous production without downtime.

7. The extruder motor and gearbox are directly connected, improving production efficiency.

8. The screen changer utilizes a hydraulic dual-screen mechanism, eliminating the need to stop the machine for screen changes. This provides convenient operation and enhanced production efficiency. 9. The machine's calendering, pulling, and winding sections (including waste edge winding) feature a separate design, aesthetically pleasing and easy to install and debug.

10. The calendering roller's inner liner features a spiral groove design, providing excellent cooling and enhanced rigidity.

11. The calendering roller can be optionally equipped with an independent temperature control system to meet diverse process requirements.

12. Optional gantry and flip-type winding machines are also available, and multi-station customization is also possible.

SPECIFICAITON

|

Applicable Materials |

PP, PS, PE |

Main Motor Power |

160kw |

|

Product Width |

PP, PE: 850mm |

Heating Power |

85kw |

|

Product Thickness |

PP, PE: 0.3-2mm |

Total Power |

235kw |

|

Effective Die Width |

1000mm |

Flow Rate |

80m³/h |

|

Effective Roller Width |

1000mm |

Line Speed |

15-30m/min |

|

Three Roller Diameters |

400mm*1 |

Production Capacity |

300-400kg/h |

|

Screw Diameter |

130mm |

Equipment Weight |

12000kg |

|

Screw Aspect Ratio |

1:36 |

Equipment Dimensions |

Length * Width * Height |

PARTNER BARANDS

Product Ordering

Please fill in the following information